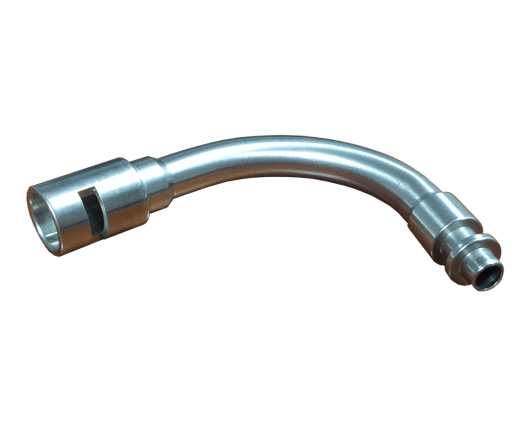

Fuel Injector System Component

Reverse Engineered for Better Design & Performance

Industry: Alternative Fuel

Project Type: Reverse Engineer, Redesign, Precision Machine and Bending

Description:

A client in the alternative fuel industry needed a special part for a vehicle that runs off propane. The original design utilized a three-piece assembly part that was being used to deliver propane within the fuel injection system. The three-piece part with two end pieces and a connecting tube with brazed joints presented issues with leakage–issues that would always be present with a multi-piece design. Furthermore, the integrity of the piece and subsequent leakage could not be identified until completely assembled. This created multiple issues, as well as inefficiencies.

Redesigned into a Single, Integral Piece

No joints and no leakage was the primary goal, and both were achieved after RD Machine was given the original brazed assembled part and original blue prints. Our engineering team reverse engineered this part and redesigned it as a solid piece. After building a prototype and extensive testing, the part went into production. We machined the part which required both deeper drilling and machining, as well as specialty bending to match the precise angle. This project was highly successful, and our customer was very happy with the end result.

Specialty Services & Technology Used:

- Reverse Engineering & Redesign

- Recreate Blueprints

- Prototyping

- Testing

- Production

- 6-Axis Turning Center

- Specialty Bending

- Specialty Internal Tooling

- Deeper Drilling and Machining

Want to get started on a project?

Request a QuoteRequest a ConsultationWe are ready to take your most demanding projects.